Industry

Top 5 KPIs: Simon Le Heron

"There's no such thing as a wrong farming system so long as you're working within the resources you've got and you know your numbers really well."

- Simon Le Heron, CEO, Grasslands

Simon Le Heron is the CEO at Canterbury Grasslands Limited (Canterbury Hub). The NZ business has 15 farms spread across the South Island, producing over 5 million kgMS. The Canterbury Hub is 3,500Ha with 9,000 cows. With a legal background, a strong technical understanding of farming, and his own farming investments, Simon puts a unique lens on the Key Performance Indicators (KPIs) he focuses on.

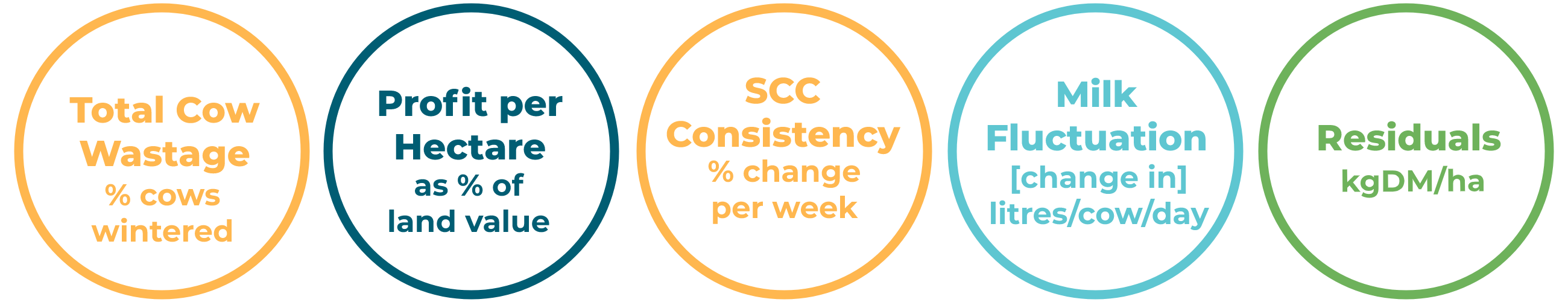

1. Total Cow Wastage (% cows wintered)

This one is fairly self explanatory. If you have low cow wastage and a high number of quality replacement stock then better discretionary culling decisions can be made, so overall herd quality improves. We aim for somewhere between 15-20% wastage which allows 5% as discretionary culls.

2. Profit per Hectare (as a % of land value)

This can be a tough metric to work out but is a really important one before purchasing land. I use this to inform my investment decisions and challenge the rationale of buying land. It provides for a solid analysis of the potential return per hectare.

Sometimes buying the best farm won’t give you the best return - so this is a great bit of due diligence to do before purchase. By analysing profit per hectare as a percentage of land value we can also factor in feed input and how that may affect return. This can make it a useful measure in terms of understanding more about the type of system you might choose to implement on a farm. For example, using high feed inputs may not result in more profit at the end of the day.

3. SCC Consistency (% change per week)

Somatic Cell Count (SCC) can be influenced by a range of on-farm factors and can therefore be a good indicator of how the farm is being managed overall. I like to review SCC on a weekly basis. What I’ve found is that if SCC is consistent, which doesn’t necessarily mean low, then the farm is being managed well. On the other hand, a change in the SCC trendline can point to an issue on-farm, such as poor shed hygiene, stressed animals, poor people management.

4. Milk Fluctuation (change in litres/cow/day)

By monitoring changes in litres in the vat on a daily basis I’m able to get a feel for how accurate the decisions that we’re making on feeding levels are for our business. Ideally we’re looking for consistency in production.

We use Levno as a live point of time indicator of what our milking volumes are doing to inform grazing decisions. This is particularly pertinent in a multi-farm environment as some things that an owner/operator might pick up straight away can take longer for us to find as a result of more layers of people in the business. The faster we can see that information the quicker we can get an indication of how things are going which gives us so much more power to respond in a timely manner.

We’ve started sharing our daily milk volume movements with the whole business in our WhatsApp group. By reviewing and sharing live data we can pick up any mistakes as they happen rather than in the past and this is really important for us so that we can make a decision ahead of the collection curve.

5. Pasture eaten (kgDM/ha)

Pasture eaten per hectare will always influence profitability. If grass is left behind, the grass quality the second time around isn’t going to be as good. And if the cows do eat into that, milk production tends to be negatively impacted which is a true cost.

This KPI ensures we are always aiming for consistent quality of feed and not giving any excuse for milk production to drop. At the end of the day grass has to be optimised, no matter what system you’re running, so hitting our target residuals is a non-negotiable.